Heritage Meets Innovation

Northey Tech specialises in the development, design and manufacture of dry and oil-free rotary compression and vacuum pumps. With over 90 years of experience, we deliver high-quality machines that are expertly designed and made with the highest degree of skill and precision.

Our world class pedigree is founded on innovation. We constantly strive to improve our products and exceed our customers’ expectations whilst ensuring our products are environment friendly. Consistent quality and constant innovation form the basis of our business, helping us drive toward the goal of becoming your trusted advisor in gas & air handling.

Our global blue-chip customers operate in the water and wastewater sector, oil and gas, nuclear, pharmaceuticals and food and beverage.

The Northey Advantage

Here at Northey Tech we are passionate about reducing environmental impact while enhancing reliability, helping you keep costs down.

Products such as our High-Speed Turbo Blowers and side channel blowers can cut carbon emissions by up to 35%, and our compressors and vacuum pumps significantly reduce running costs due to the low maintenance and part replacement requirements.

Our blower, compressors and vacuum pumps are all dry and oil-free - which is particularly vital within clean manufacturing environments such as food packaging and processing, beverage, pharmaceuticals, laboratories and medical as there is no risk of oil contamination.

We understand every business is unique – which is why our team of specialists can work with you to create bespoke products suitable for your needs.

All our products offer a low energy, low maintenance solution with an outstandingly low total cost of ownership or total expenditure (TOTEX) over their lifetime.

Here are just some of the key advantages to choosing Northey, based on our customers’ feedback:

- Save up to 35% in energy costs and carbon consumption

- Ultra-low maintenance requirements – every two years on average

- No lubricating fluid - saving thousands of pounds on oil consumption

- No lubricating or sealing fluid required- removing risk of contamination to product or environment

- Long mean time between failures (MTBF)

- Customisable for your application

- Adaptable for challenging environments including potentially explosive atmospheres (ATEX), toxic or cryogenic applications

- Options on corrosion-resistant components and coatings

Continually Innovating for Complex Problems

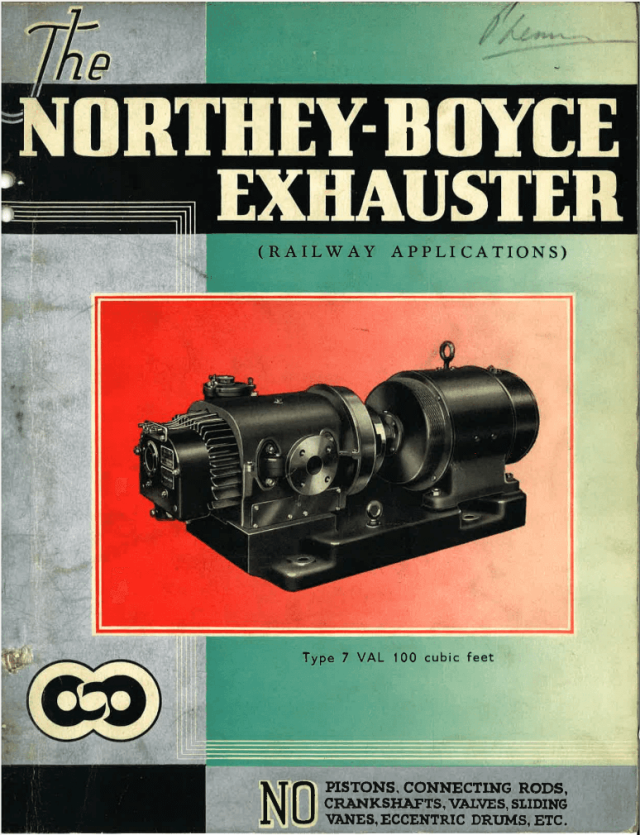

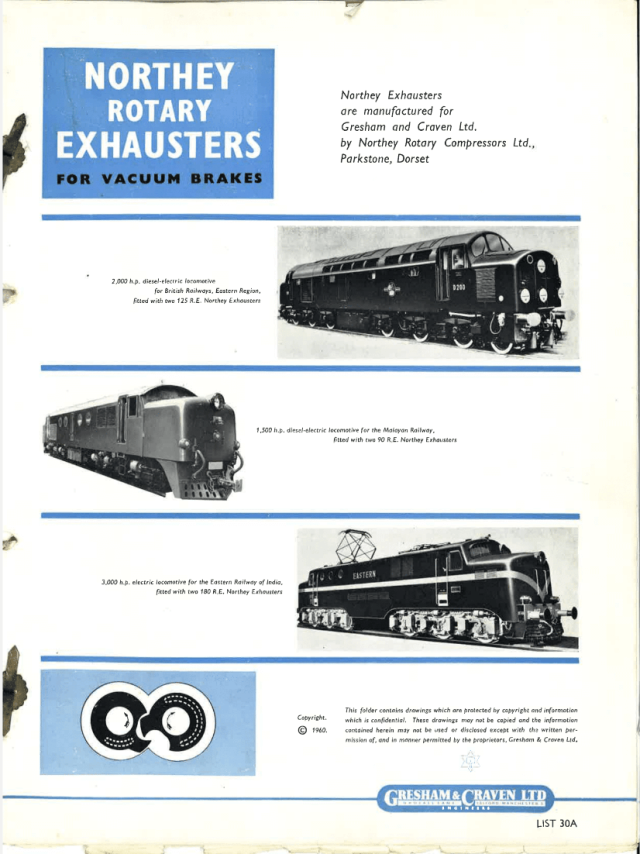

We take our name from founder and inventor Mr A. J. Northey, who invented the Hook & Claw device as a rotary engine in the 1920s, adapting it as a dry vacuum pump and compressor in the 1930s.

From the original applications of the Hook & Claw as a supercharger [an air compressor that increases the density of air supplied to an engine] for cars and on vacuum pumps for railway braking systems, we have continually developed and extended our product range.

Timeline:

1935

- Hook & Claw vacuum pump and compressor Invented

1937

- Patent application for Hook & Claw approved

- Creation of Northey Boyce Rotary Engineering Company Limited

- Listed exhibitor at the British Industries Fair showing Patent Rotary Compressors and Exhausters

1946

- Creation of Northey Rotary Compressors Ltd

- Invention of Northey Rotary Compressors

- Invention of Railway Exhauster

1950s

- Classified Ministry of Defence applications including Atomic Weapons Research Establishment

1960s

- Gas mixing for biogas developed with UK water authorities

1970s

- Seal-less vacuum pump developed with British Nuclear Fuels for uranium enrichment process

- Oil-free air used for whiskey blending

1980s

- Various aircraft and avionics applications including electronics cooling systems

- First vacuum pumps used for vapour deposition in semiconductor chip manufacturing

- Used extensively by gas suppliers such as BOC to produce noble gases like argon

- Exports to Singapore and Hong Kong for biogas applications

1990s

- Developed equipment for cryogenic applications for companies like Air Products, including the cold nitrogen blower, which could handle temperatures down to -193oC

2000

- Developed equipment for handling toxic gases such as fluorine

- Creation of Northey Tech Ltd

2010s

- Developed new range of Tiger compressor and vacuum pumps

2020

- First High-Speed Turbo Blower with air bearing introduced for aeration in UK wastewater treatment applications

We've Made the Most of our 75 Years

If you are interested in our history, please get in touch – we’ve plenty more to tell you!

Protecting People and The Environment

We are committed to planning and operating in an environmental, social, and economically sustainable manner.

Northey recognises the impact we have on the planet and our Corporate Social Responsibility (CSR) policies are designed to protect and enhance the environment through sustainable procurement, management and collaborative practises.

We engage in water, energy and carbon savings at our headquarters to reduce our environmental footprint and frequently refresh our policies to ensure the sustainability of our company and supply chain.

People are at the heart of everything we do, and we strive to ensure all our employees work in a safe and healthy environment. We respect and comply with the law, and do not tolerate slavery, discrimination or corruption.

We take our role in the community very seriously, and our employees enjoy fundraising for local charities and projects, including Shepherds Down School, a community special school in Winchester.

Find out more about our Corporate Social Responsibility Practices.

Experience and Expertise at Every Level

Bernard Whicher

CEO

Glyn Cockwell

Production Manager

Kay Hinc

PA to Managing Director

John Rogers

Engineering Project Manager

Jorge Molcholi

Engineering Service

Andrejs Gerasimovs

Production Fitter & Welder

Tony Palmer

CNC Machinist

Liz Shirkhani

Customer Services

Ollie Holland

Project Engineer

Northey is an Equal Opportunity Employer

We are constantly looking for highly motivated and passionate individuals to join our close-working team. Northey is made up of a diverse range of talented individuals, who are all experts in their fields. If you are interested in working with us, please get in touch on 01202 668732 or email kay.hinc@northey.net

Ready to jump right in?

Check out our current vacancies on our LinkedIn page!

Are you ready to talk?

Our specialists are ready to help. If you have a question about one of our products, need advice selecting a solution or you’re after maintenance or service from our engineers, please don’t hesitate to get in touch.